1060 O Aluminium Strips For Transformers Winding

Your Premier Transformer Winding Aluminium Strips Manufacturer

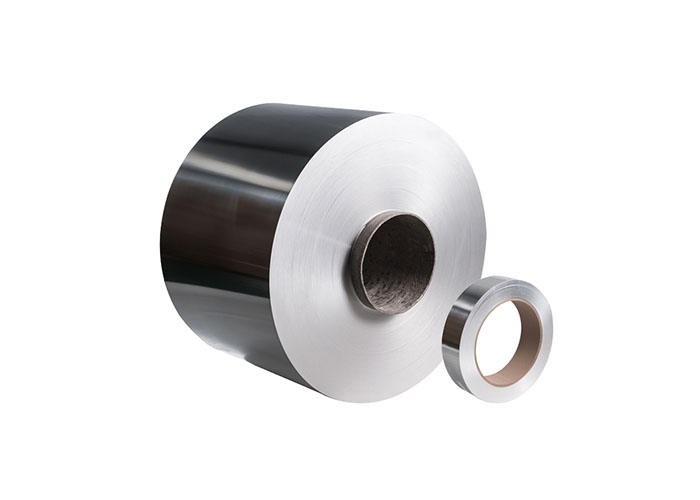

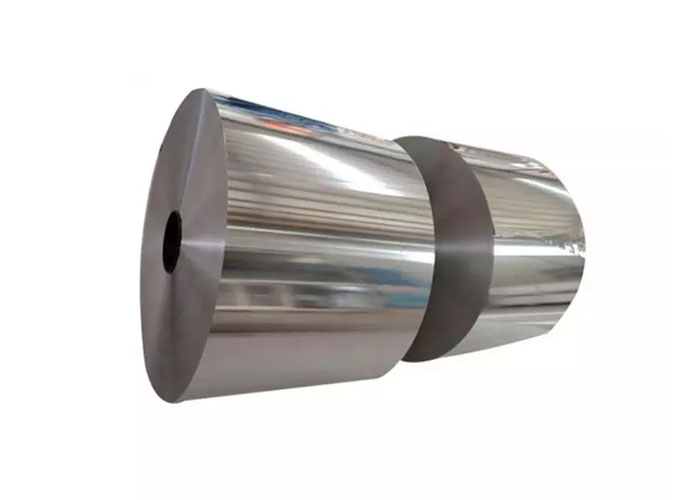

1060 O Aluminium Strips For Transformers Winding

Grade 1060 O aluminium strips for transformers winding are pure aluminum strips, the content of aluminum can reach more than 99.6%.

1060 aluminum foil strip is the most commonly used alloy strips in transformer manufacturing industries.

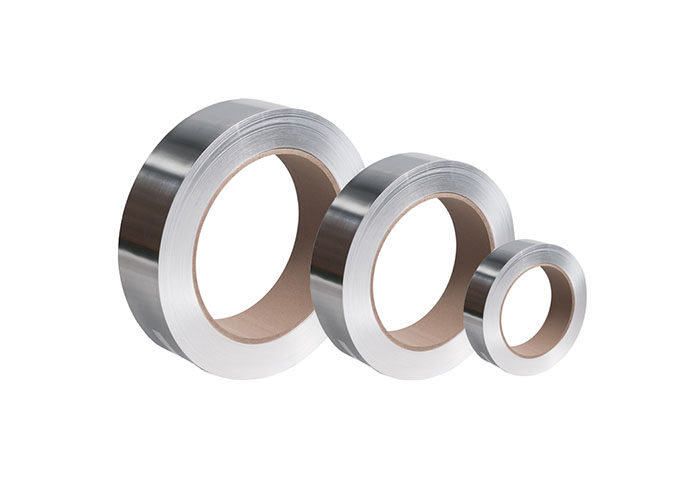

1060 O Aluminium Strips For Transformers Winding Specifications

| Product Name | 1060 O transformers winding aluminium strips |

| Grades | 1060 |

| Temper | O |

| Thickness | 0.1mm-3.5mm |

| Width | 10mm-1600mm |

| Edge | Slit/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Finish | The strip has a smooth surface, free from scratches and impurities |

| Electrical Conductivity | Transformer windings made of 1060 O in annealed condition is guaranteed to be better than 61.5 % ACS. |

| Applications | Transformer winding |

| Packaging | Wooden Pallets/Wooden Cases |

| Payment Terms | 30% T/T deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 5 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of 1060 aluminium strip is available |

| Remark | Grade 1060 aluminium strip can be customized |

1060 O Aluminium Strips For Transformers Winding Features

- Super Thin, No Burrs

- Round Edge

- High Conductivity

- High Purity

- Totally Annealed

- Good Reputation

- High Strength

1060 O Aluminum Strips For Transformers Chemical Composition

| 1060 O Aluminum Strips Chemical Composition(%) | |||||||||

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

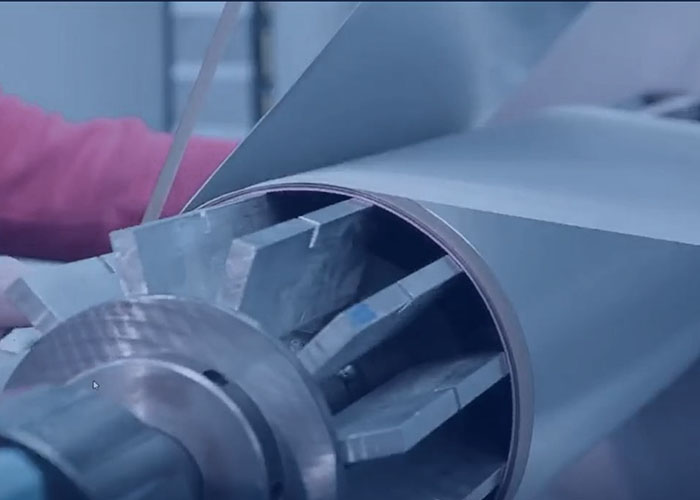

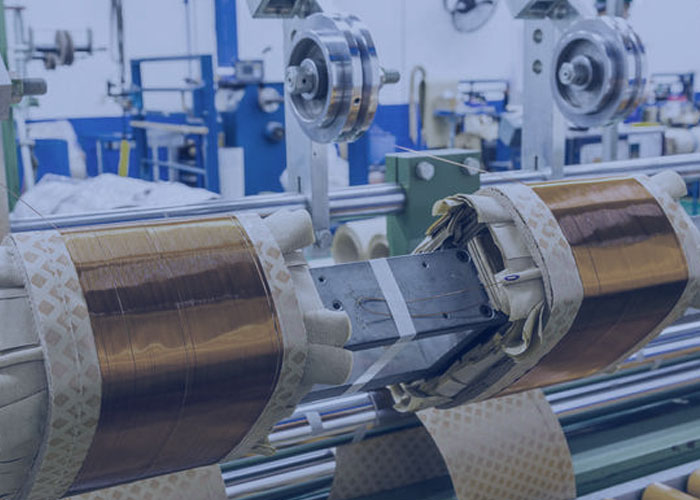

1060 O Aluminium Strips For Transformers Winding Edges Innovation Technology

Our technical expert have studied for this project a long time, we have found a solution to strip edge problem. The edge finishing of our aluminium strips shall meet the requirements of the figures show.

Your Reliable 1060 O Aluminium Strips For Transformers Winding Manufacturer In China

1060 O Aluminium Strips For Transformers Winding: The Ultimate Guide

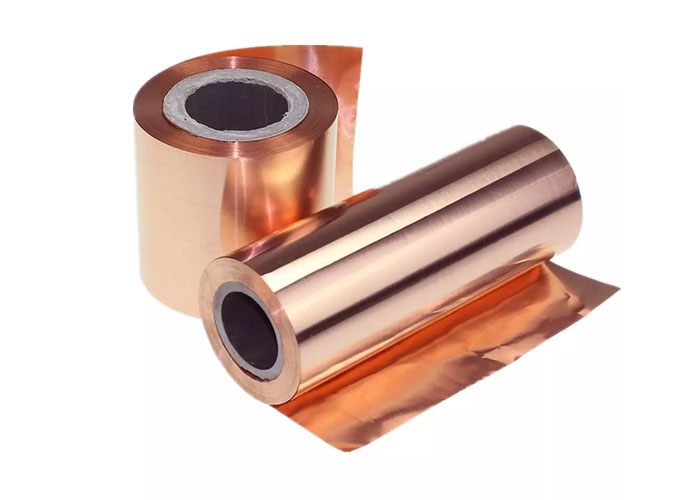

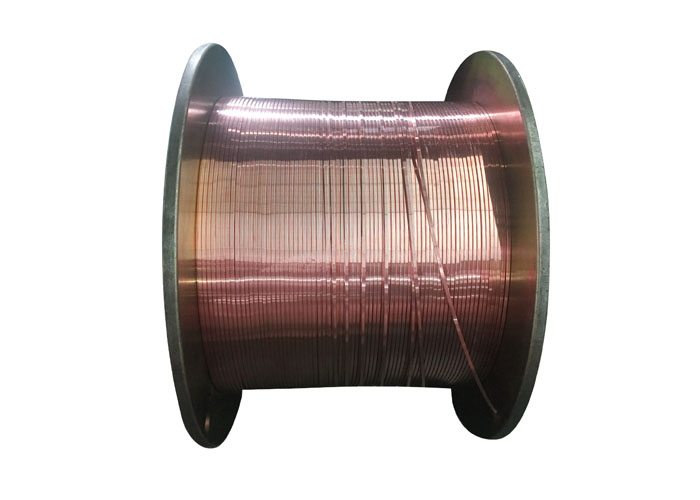

Aluminum strips are one of the most important metal materials in transformer winding industry.

When you choose to buy 1060 O transformers winding aluminium strips, there have some important points we need to know before we get started.

What are the advantages of using 1060 O aluminum strips for transformers applications?

In terms of material selection and production process control, 1060 O temper aluminum strip has outstanding advantages:

- High conductivity: The conductivity of 1060 O state aluminum strip is higher than that of 1 series, 3 series and 5 series aluminum alloy strips, which can save copper strip cost;

- Excellent elongation: The elongation of 1060 O state aluminum strip for transformers is higher than that of 1 series and 8 series alloy strips, so it can better meet the requirements of stretching and forming;

- Good processability: 1060 O state aluminum strip has good processability under normal conditions, which can ensure the quality consistency of products;

- Excellent oxidation effect: Compared with other alloys, 1060 O state aluminum strip has better oxidation effect, which can improve product quality and service life;

- High flatness: The flatness error of 1060 O state aluminum strip produced by us are less than 1/1000.

How to buy 1060 O aluminum strips for transformers?

To get a quick quote for 1060 O temper aluminium strips you need to know:

- Quantity (Kgs/tons)

- Size (Thickness x width x coil)

- Temper (O soft)

- Material Grade (1060, etc)

- Edge (Slit/deburred/round)

- Coil ID (200mm/300mm/400mm/500mm)

- Surface Finish (Sliver aluminum color)

- Packaging (Eye to eye, eye to wall, wooden pallets, wooden cases)

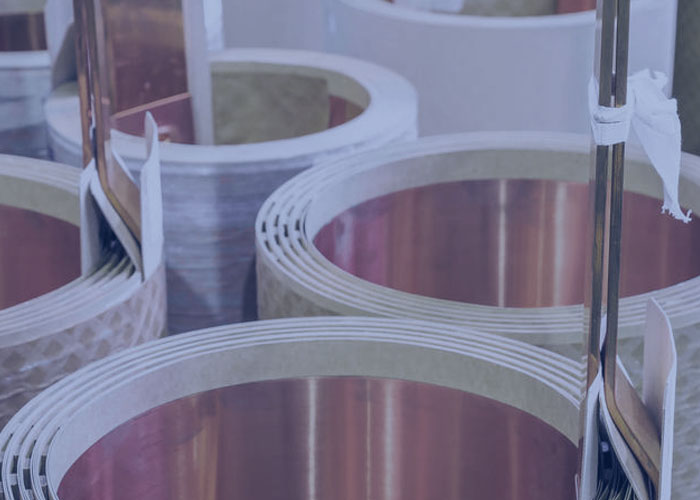

What are 1060 O transformer aluminum strips packaging?

- Standard export wooden pallets or wooden cases.

- Also we can meet special requirements from our customers.

- Deliver in coil, hard paper core inside, with paper interleaved.

- Eye to wall and eye to sky are both available.