Copper Busbars

Your Premier Transformer Copper Busbars Manufacturer

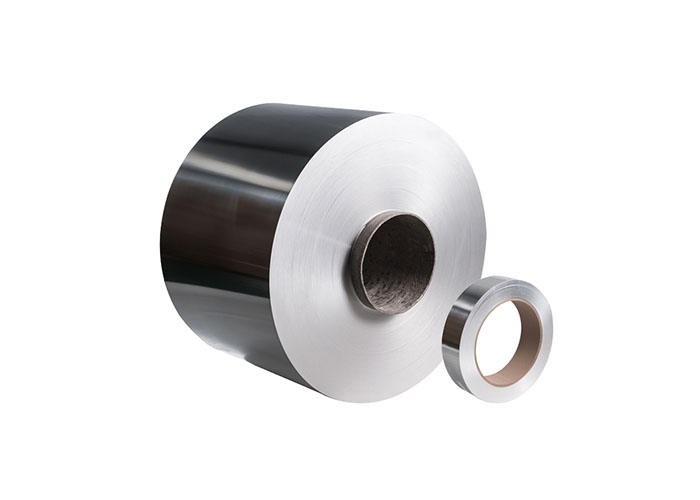

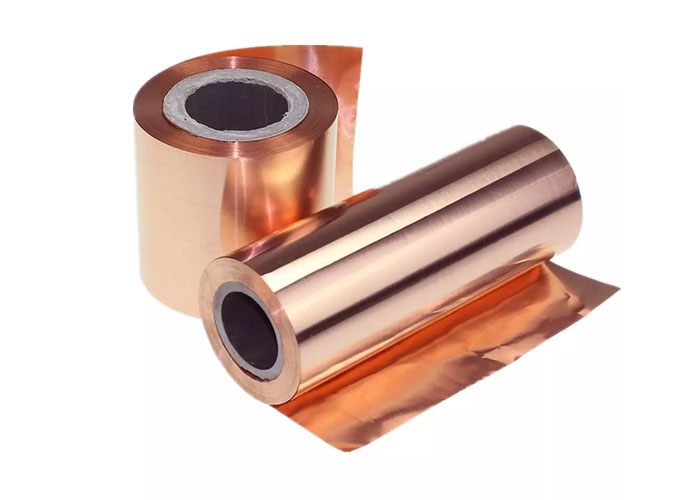

Copper Busbars

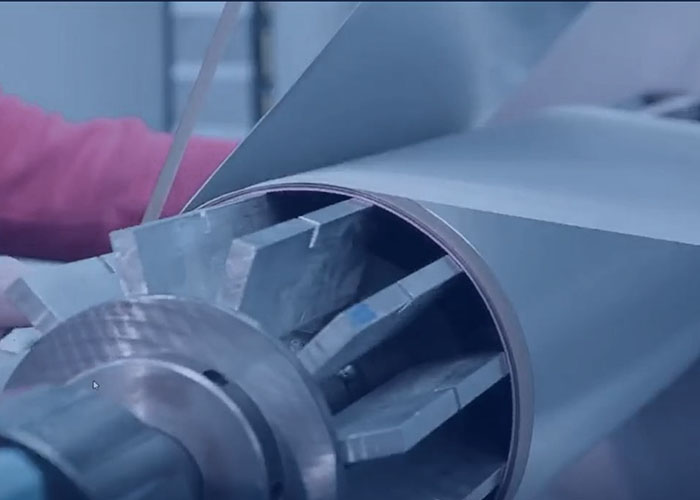

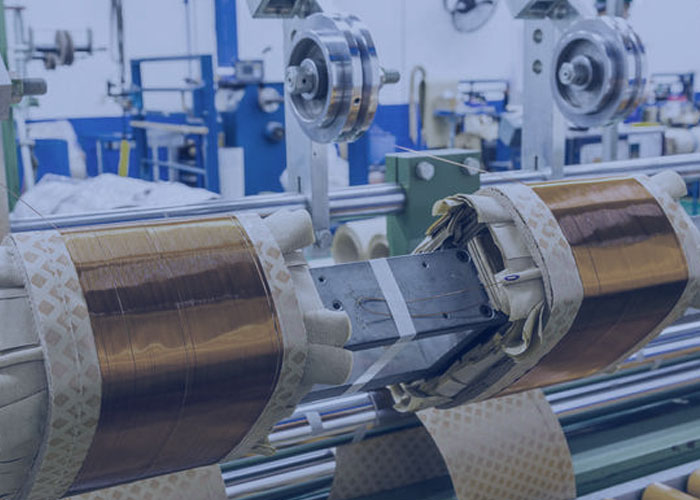

Copper busbars have high electrical and thermal conductivity, durability and malleability, which are widely used in transformers, reactors, filters and mutual inductors.

There is no burr on the edge of copper busbars. Surface atomization treatment makes the surface of copper strip get to a brighter and cleaner level.

Copper Busbars Specifications

| Matetrial | Copper T2, C11000, C10200 | Hardness | Min 65 |

| Electrical Busbars thickness | 0.5mm,1.0mm, 2.0mm,3.0mm or as your requirements | Electrical Busbars Length | It is up to 6000mm max |

| Other dimension | As to customer’s confirmed drawings | Plating | Tin/nickle/silver/others |

| Insulation | Heat shrink sleeve/pvc dip/bare aluminum | Warranty | 20 years |

| Certificate | ISO&SGS | Main Process | Cutting, punching, stamping, drilling, twisting, testing |

| Delivery | 5-7 days | MOQ | 10 Pieces |

| OEM | Custom all types of Electrical Busbars | Application | Electric vehicle battery, power distribution equipment, rail applications, outdoor distribution box, etc |

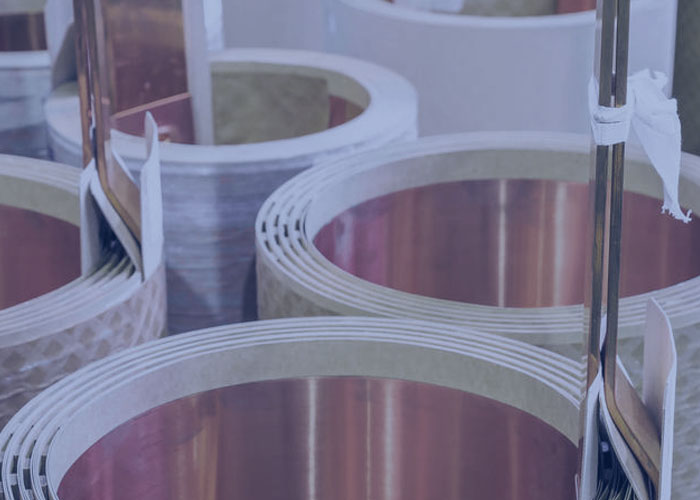

Copper Busbars Packaging

Copper busbars packing can be done by wooden case and cartons. The wooden case and copper electrical busbars contact parts must be padded with foamed paper or rubber.

Case four corners shall not be smaller than the size of the copper electrical busbars.

Copper busbars surface finish wrapping foam paper, four sides contacting with wooden case with foam mat protection.