Copper Foils For Transformer Winding

Your Premier Copper Foils For Transformer Winding Manufacturer

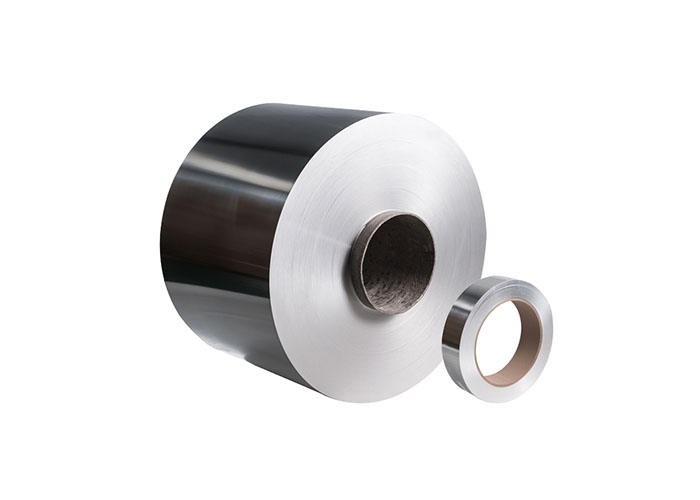

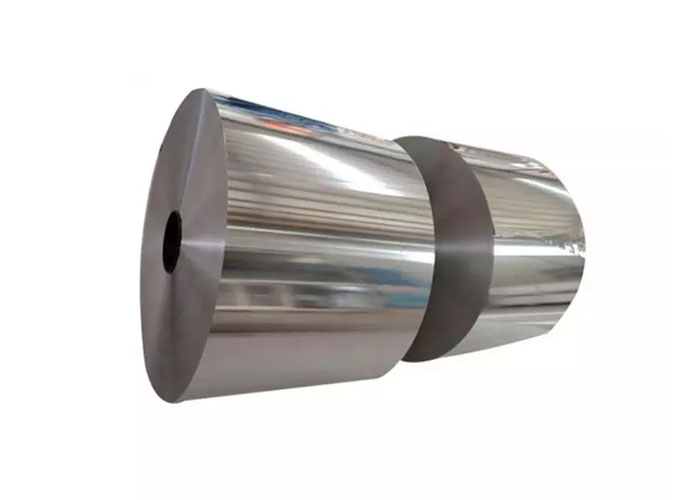

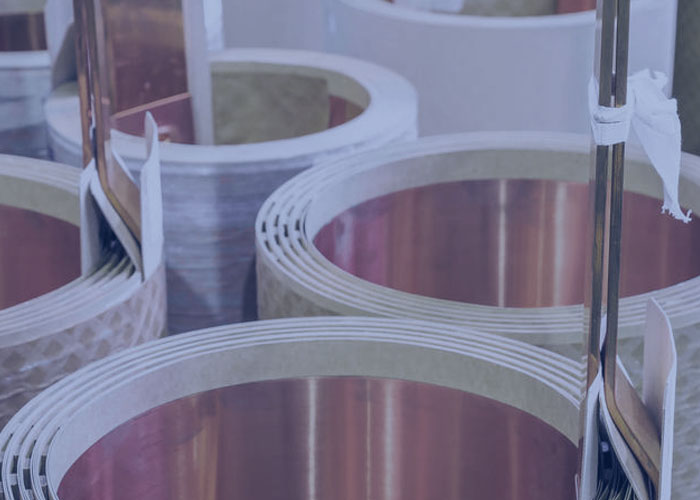

Copper Foils For Transformer Winding

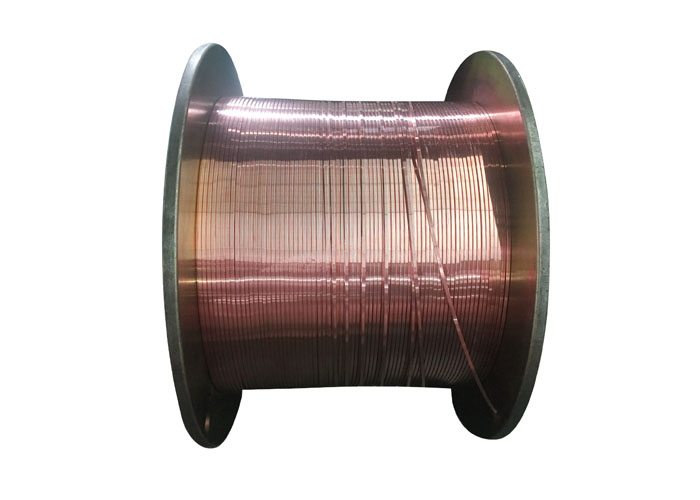

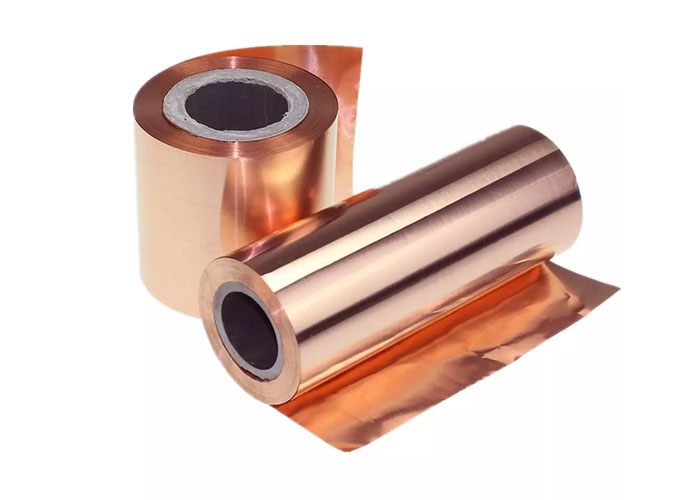

Copper foils for transformer winding, also called transformer copper super thin strips, are mainly used in the transformers manufacturing industries.

The commonly used copper grades are ETP Grade (Electrolytic Tough Pitch), C11000, UNS C10200 TU1, temper O state.

The thickness of copper foil is usually between 0.01mm-3.0mm.

The transformer winding copper foil can be customized according to customer requirements of different widths and thicknesses.

Transformer Winding Copper Foils Specifications

| Product Name | Transformer Winding Copper Foils |

| Grades | C1100/C11000/Cu-ETP/UNS C10200 TU1 |

| Temper | O Soft |

| Thickness | 0.01mm-3.0mm |

| Width | 5mm-1200mm |

| Edge | Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Treatment | Mill finish, the strip has a smooth surface, free from scratches and impurities |

Electrical Conductivity (20℃)(IACS) | ≥99.80% |

| Applications | Transformer winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500 Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of copper foil is available |

| Remark | Transformer copper foil can be customized |

Copper Foils For Transformer Winding Features

1. Super Thin, No Burrs and no scratch

2. Totally annealed

3. High strength

4. Above 99.80% IACS high electric conductivity

5. Excellent side camber 2mm/meter

Transformer Winding Copper Foils Grades Comparison

INDUSTRY | USA | ITALY | CHINA | EURONORM | JAPANESE | |

STANDARD | ASTM B5, B152 | UNI 5649 | GB/T | EN 1652 | DIN 1976 | JIS |

C1100 | C11000 | Cu-ETP | T2 | CW004A | E-Cu 58 | C1100 |

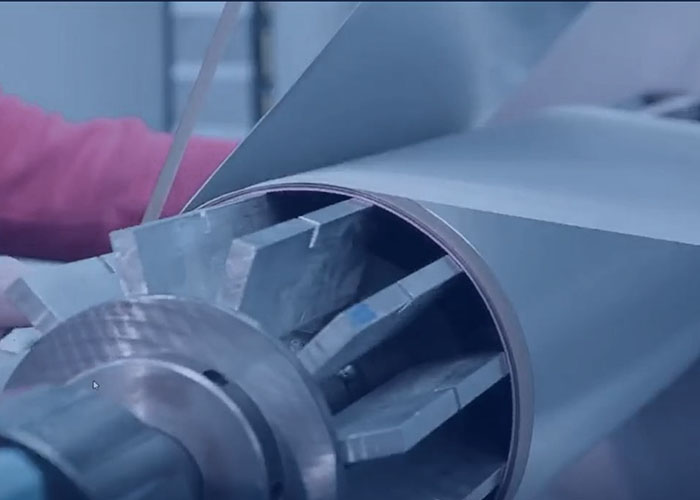

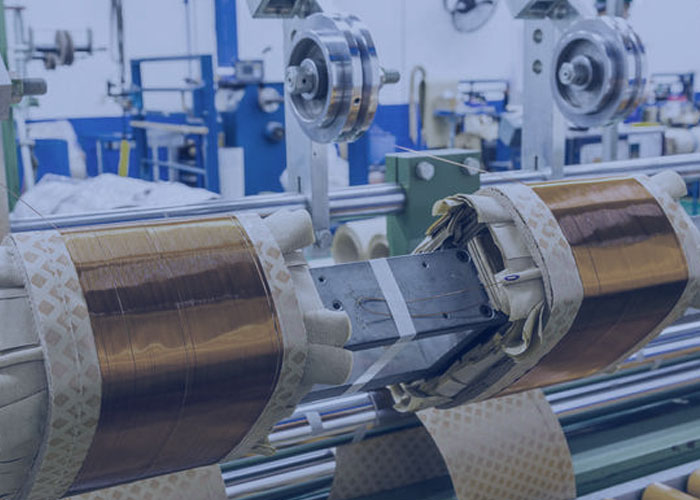

Copper Foils For Transformers Winding Edges Innovation Technology

Our technical expert have studied for this project a long time, we have found a solution to strip edge problem. The edge finishing of our copper foils shall meet the requirements of the figures show.