Copper To Aluminium Adapter Board Bimetal Busbars

Copper To Aluminium Adapter Board Bimetal Busbars

Due to the coupling effect when aluminium comes in contact with copper, corrosion will happen in a short time.

Currently the best solution is to use aluminium-copper bimetal connectors.

A bimetal lug should be used for termination. The friction welding is well done. And its barrel capped is filled with joint compound to avoid oxidization. The type test is follow IEC 61238-1. We are able to produce special bimetal lugs on request.

Copper To Aluminium Adapter Board Bimetal Busbars Specifications

| Matetrial | Copper T2, C1100, C10200 | Aluminium | 1050/1060/1070 |

| Electrical Busbars thickness | 0.5mm,1.0mm, 2.0mm,3.0mm or as your requirements | Electrical Busbars Length | It is up to 6000mm max |

| Other dimension | As to customer’s confirmed drawings | Plating | Tin/nickle/silver/others |

| Insulation | Heat shrink sleeve/pvc dip/bare aluminum | Warranty | 20 years |

| Certificate | ISO&SGS | Main Process | Cutting, punching, stamping, drilling, twisting, testing |

| Delivery | 5-7 days | MOQ | 10 Pieces |

| OEM | Custom all types of Electrical Busbars | Application | Electric vehicle battery, power distribution equipment, rail applications, outdoor distribution box etc |

Copper To Aluminium Adapter Board Bimetal Busbars Features

- Super Thin, No Burrs

- High Conductivity

- High Purity

- Good Reputation

- High Strangth

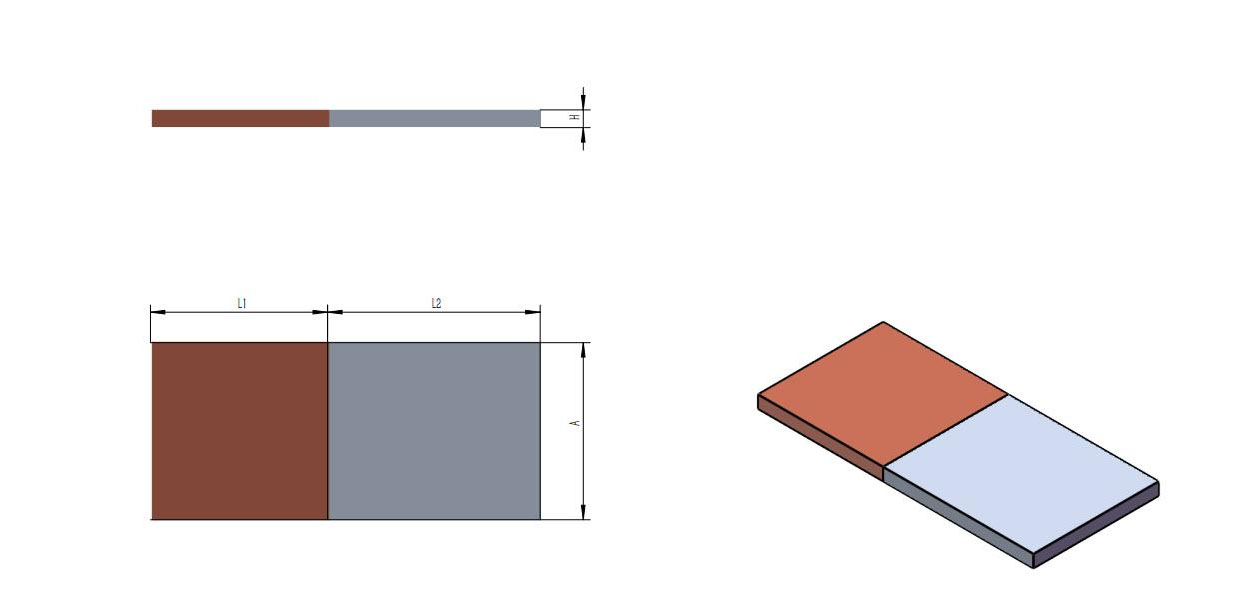

Copper To Aluminium Adapter Board Bimetal Busbars Technical Data Sheet

| Type | Busbar Specifications | Main Dimensions(mm) | |||

| A | B | L1 | L2 | ||

| HIGHV-50X5 | 50X5 | 50 | 5.0 | 50 | 60 |

| HIGHV-60X6 | 60X6 | 60 | 6.0 | 60 | 80 |

| HIGHV-63X6.3 | 63X6.3 | 63 | 6.3 | 65 | 88 |