Transformer Winding Copper Strips

Your Premier Transformer Winding Copper Strips Manufacturer in China

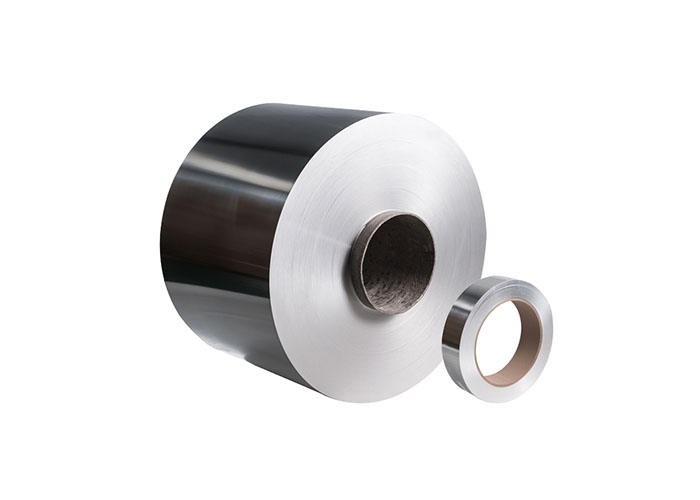

Transformer Winding Copper Strips

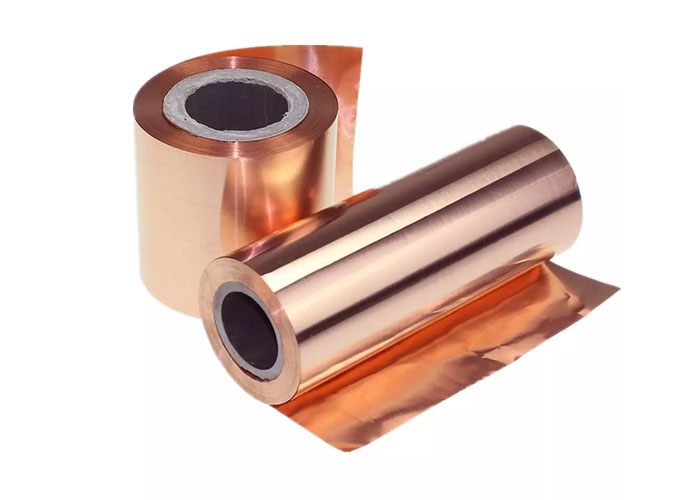

Transformer winding copper strips, also called copper strips foils for transformer winding, are mainly used in the transformers manufacturing industries.

The commonly used copper grades are ETP Grade (Electrolytic Tough Pitch), C11000, UNS C10200 TU1, temper O state.

The thickness of copper strip is usually between 0.01mm-3.0mm.

The transformer winding copper strip can be customized according to customer requirements of different widths and thicknesses.

Transformer Winding Copper Strips Specifications

| Product Name | Transformer Winding Copper Strips |

| Grades | C1100/C11000/Cu-ETP/UNS C10200 TU1 |

| Temper | O Soft |

| Thickness | 0.01mm-3.0mm |

| Width | 5mm-1200mm |

| Edge | Deburred/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm, Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

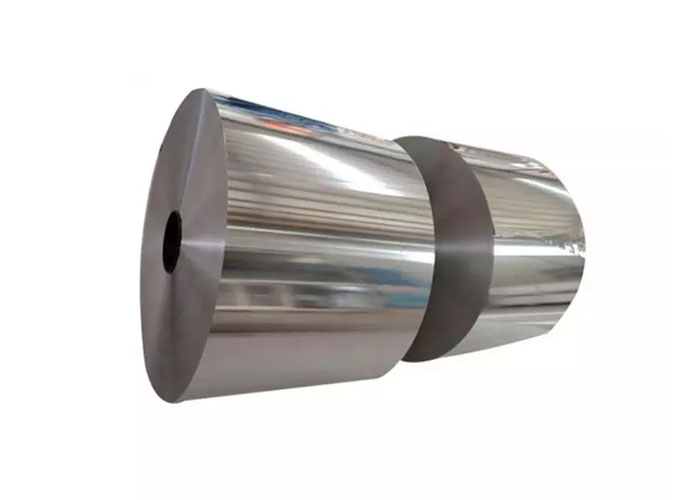

| Surface Treatment | Mill finish, the strip has a smooth surface, free from scratches and impurities |

Electrical Conductivity (20℃)(IACS) | ≥99.80% |

| Applications | Transformer winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 500 Kgs |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of copper strip is available |

| Remark | Transformer copper strip can be customized |

Transformer Winding Copper Strips Features

1. Super Thin, No Burrs and no scratch

2. Totally annealed

3. High strength

4. Above 99.80% IACS high electric conductivity

5. Excellent side camber 2mm/meter

Transformer Winding Copper Strips Grades Comparison

INDUSTRY | USA | ITALY | CHINA | EURONORM | JAPANESE | |

STANDARD | ASTM B5, B152 | UNI 5649 | GB/T | EN 1652 | DIN 1976 | JIS |

C1100 | C11000 | Cu-ETP | T2 | CW004A | E-Cu 58 | C1100 |

Transformer Winding Copper Strips Chemical Compositions

| C1100/C11000 Copper Strips Chemical Composition(%) | ||||||||

| Element | Cu+Ag | Sn | Zn | Pb | Ni | Fe | As | O |

| Standard Value | ≥99.90 | ≤0.002 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.005 | ≤0.002 | ≤0.06 |

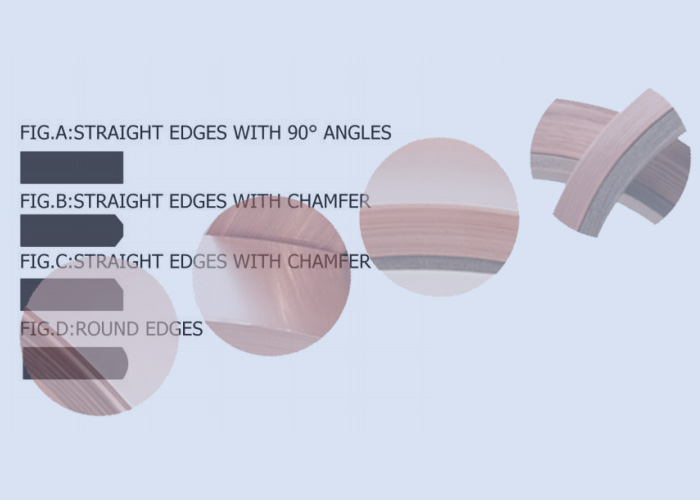

Copper Strips For Transformers Winding Edges Innovation Technology

Our technical expert have studied for this project a long time, we have found a solution to strip edge problem. The edge finishing of our copper strips shall meet the requirements of the figures show.

Your Reliable Transformer Winding Copper Strips Manufacturer In China

Transformer Winding Copper Strips: The Ultimate Guide

This guide will cover what you need to know about choosing the best copper strips for your transformer’s project needs, including:

What are transformers copper strips?

Why use copper strips instead of other conductors?

How are copper strips made?

Want more? Let’s keep reading!

What are the transformers copper strips?

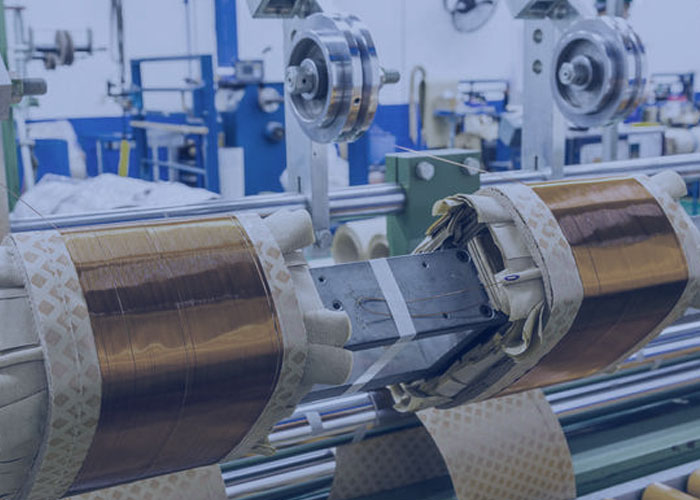

Copper strip is made by rolling copper to a very thin thickness (between 0.01mm and 3.0mm) and then cold-rolling or hot rolling depending on the required thickness. This can be followed by annealing (for even greater flexibility) and further processed into strips or laminated sheets with insulation materials.

The majority of copper foil is used in dry-type transformers and small transformers, where they are wound together with insulating materials.

What are the advantages of using copper strips for transformers?

As a result of the low percentage of impurities, copper strip for transformer winding with over 99.8% IACS high electrical conductivity, durability and malleability is widely used in transformers, reactors, filters and mutual inductors.

There is no burr on the edge of copper strip for transformer winding. Surface atomization treatment makes the surface of copper strip foil to get to the brighter and cleaner level.

How to buy copper strips for transformers?

Buyers should find and purchase their transformer copper strips needs through sourcing from manufacturers and distributors.

To buy copper strips, the buyer should consider:

- The supplier’s experience in the industry.

- The quality of goods manufactured by the supplier.

- The financial stability of the supplier.

- The supplier’s delivery system.

To get a quote for copper strips you need to know below information:

- Quantity (Kgs/Tons)

- Size (Thickness x Width x Coil)

- Material Grade (C11000, etc)

- Edge (Deburred/Round)

- Coil ID (200mm/300mm/400mm/500mm)

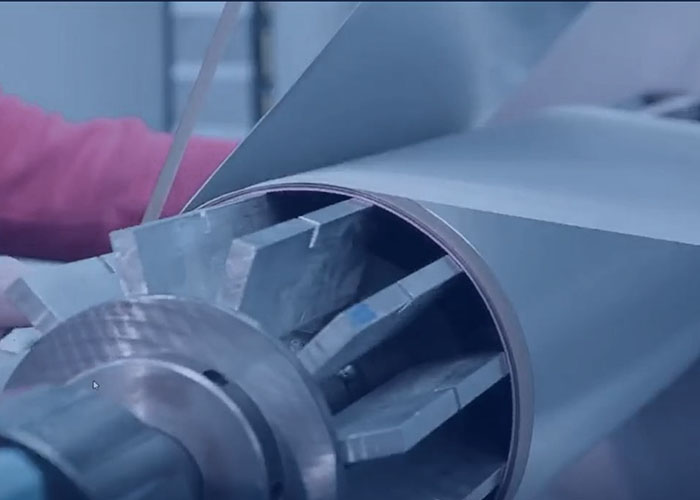

How about transformer copper strips production process?

Copper foils strips for transformers winding production process is to use the continuous casting and rolling method to produce long copper strips.

The general production process of copper strips is:

1.Copper ingot cast into semi-finished product;

2.The semi-finished product is rolled into a finished product;

3.The finished product is annealed, and then annealed, bundled according to specifications, and aged;

4.Use appropriate packaging for storage or transportation

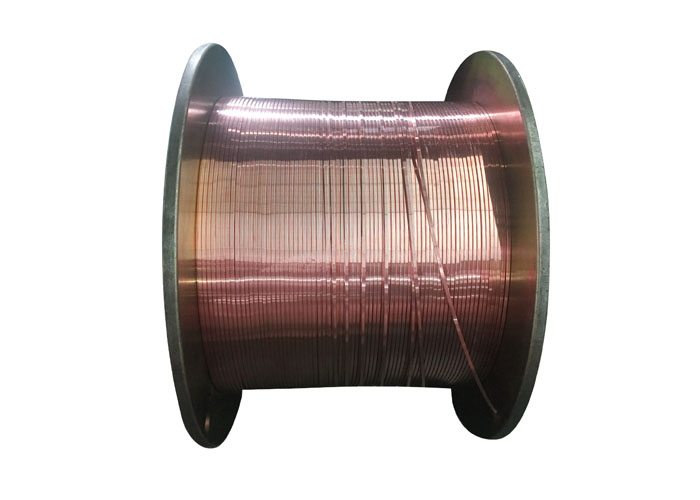

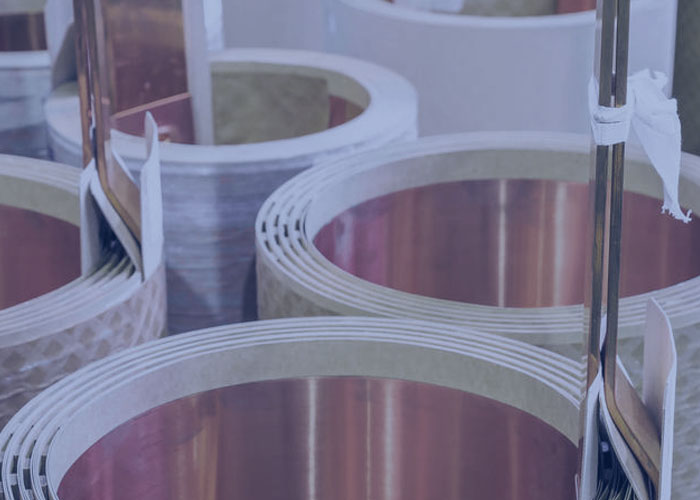

What are transformer copper strips packaging?

- Standard export wooden pallet or wooden case. Also we can meet special requirements from our customers.

- Deliver copper strip in coil, hard paper core inside.

- Eye to wall and eye to sky are both available.

- Grate car is taken to avoid any damage which might be caused during storage or transportation.

- In addition, clear labels are tagged on the outside of the packages for easy identification of the copper strip for transformer winding.