Transformer Winding Aluminium Strips

Your Premier Transformer Winding Aluminium Strips Manufacturer in China

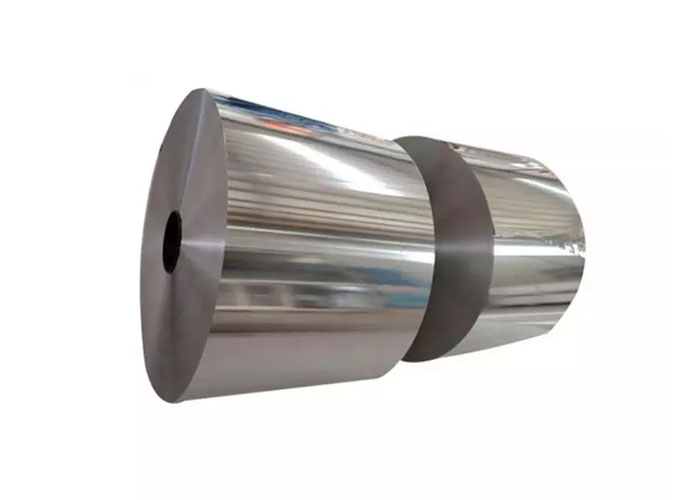

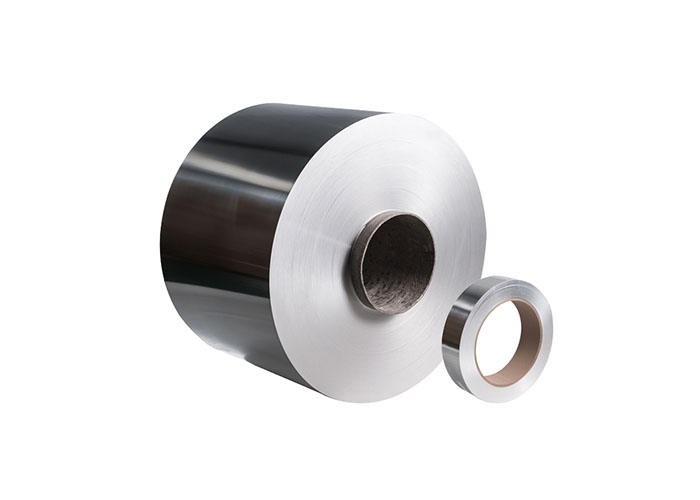

Transformer Winding Aluminium Strips

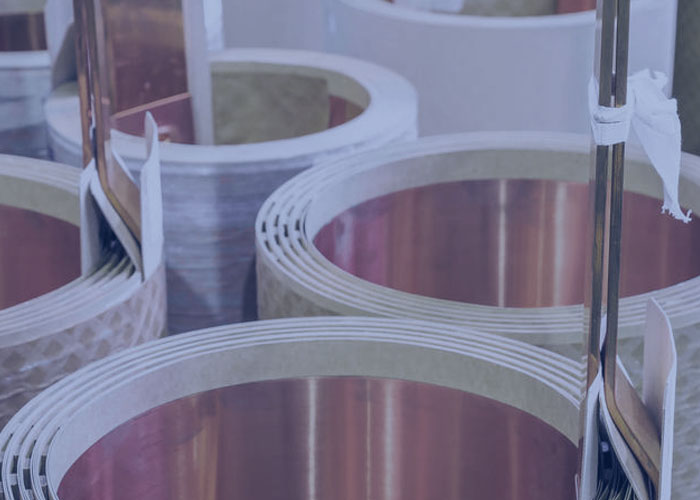

Transformer winding aluminium strips, also called aluminum strips foils for transformer winding, are mainly used in the dry type transformers manufacturing industries.

The commonly used aluminum grades are 1060, 1050, 1070, 1350, temper O state.

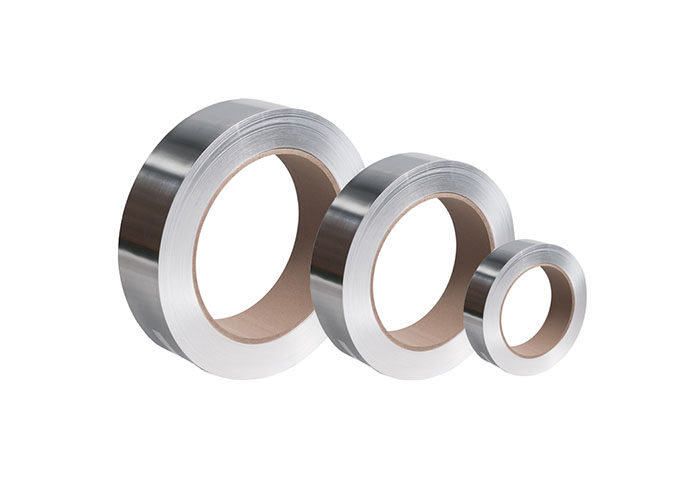

The thickness of strip is usually between 0.2mm-3.5mm.

The transformer winding aluminum strip can be customized according to customer requirements of different widths and thicknesses.

Transformer Winding Aluminium Strips Specifications

| Product Name | Aluminum strips for transformers winding |

| Al Grades | 1050, 1350,1060,1070 |

| Temper | O |

| Thickness | 0.2mm-3.5mm |

| Width | Width:10mm-1600mm |

| Edge | Slit/Round |

| Quantity Tolerance | ±10% |

| Paper Core Internal Diameter | Ø 150mm,Ø300mm, Ø400mm, Ø500mm paper core, special internal diameter core and without paper core on special request |

| Surface Treatment | The strip has a smooth surface, free from scratches and impurities |

| Electrical Conductivity | Transformer windings made of 1050 O in annealed condition is guaranteed to be better than 60.0 % ACS. Transformer windings made of 1060 O in annealed condition is guaranteed to be better than 61.5 % ACS. Transformer windings made of 1070 O in annealed condition is guar-anteed to be better than 62.7 % ACS. Transformer windings made of 1350 O in annealed condition is guaranteed to be better than 62.0 % ACS. |

| Applications | Transformer winding |

| Packaging | Wooden Pallet/Wooden Case |

| Payment Terms | 30% TT deposit and 70% balance before shipment, 100% LC at sight |

| Delivery Time | 7-10 working days |

| MOQ | 5 Tons |

| Shipping Port | Shanghai/Ningbo port |

| Sample | The sample of aluminium strip is available in Highv stock |

| Remark | Aluminium strip can be customized |

Transformer Winding Aluminium Strips Features

- Super Thin, No Burrs

- Round Edge

- High Conductivity

- High Purity

- Totally Annealed

- Good Reputation

- High Strangth

Aluminum Strips For Transformers Chemical Composition

| 1050 O Aluminum Strips Chemical Composition(%) | |||||||||

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1060 O Aluminum Strips Chemical Composition(%) | |||||||||

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.6 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1070 O Aluminum Strips Chemical Composition(%) | |||||||||

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.7 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

| 1350 O Aluminum Strips Chemical Composition(%) | |||||||||

| Element | Al | Si | Fe | Mg | Zn | Mn | Ti | Cu | V |

| Standard Value | ≥99.5 | 0.0431 | 0.203 | 0.0013 | 0.0093 | 0.0104 | 0.02 | 0.0022 | 0.0039 |

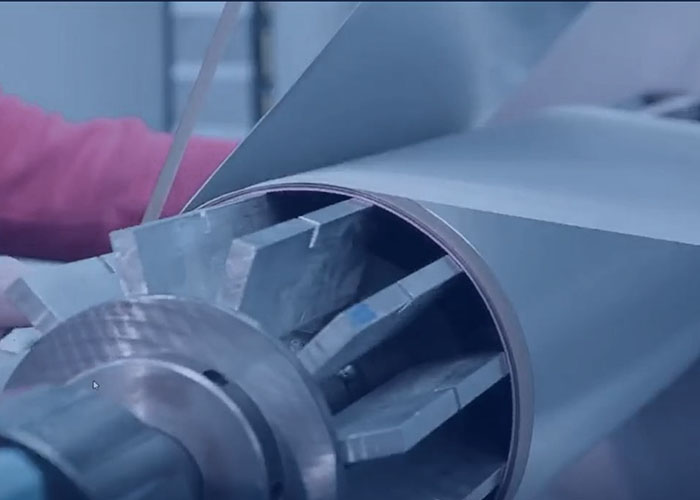

Aluminium Strips For Transformers Winding Edges Innovation Technology

Our technical expert have studied for this project a long time, we have found a solution to strip edge problem. The edge finishing of our aluminium strips shall meet the requirements of the figures show.

Your Reliable Transformer Winding Aluminium Strips Manufacturer In China

Transformer Winding Aluminium Strips: The Ultimate Guide

Aluminum strips are one of the most important metal materials in transformer winding industry.

When you choose to buy transformer aluminum strips, there have some important points we need to know before we get started.

What are the grades of transformers aluminum strips?

1.What is the 1050 O aluminum strip in a transformer?

The 1050 O aluminum strip in a transformer is the most commonly used material in transformers.

The reason why it can be widely used in transformers is related to its excellent properties.

1050 O aluminum strip has high electrical conductivity and thermal conductivity. In the actual application process of transformers, 1050 O aluminum strips are often used as support materials to form transformer windings, which can reduce the loss of transformers and improve the performance of transformers.

The thickness of the 1050 O aluminum strip in a transformer is generally between 0.1 mm and 1 mm. It adopts a single-layer or double-layer structure, which can effectively reduce the leakage magnetic field of the coil and improve its insulation performance.

The transformer 1050 O aluminum strip is a kind of connecting material for winding coils, which is wound on the coil in a certain way to form a specific inductance, mutual inductance or distributed capacitance. In addition to this kind of connection material, there are other forms of connection between coil turns, such as soldering connections and welding connections.

2.What is the 1060 O aluminum strip for transformer winding?

1060 O aluminum strip for transformer winding, the content is 99.6%, mainly used for some high and low voltage electrical equipment, such as various transformers winding. The common state is O state, so it is also called aluminum strip for transformer winding.

The aluminum strip in the electrical equipment industry has very high requirements on its performance, which requires the flexibility of the aluminum belt to be good enough.

This requires that the 1060 O aluminum strip for transformer winding has a very high elongation. In addition, it should have a good crack resistance and uniformity. meet

1060 O aluminum strip for transformer winding is mainly made of 1 series pure aluminum strip product, tensile strength can reach more than 135Mpa, elongation is up to 15%, the finished product has good electrical conductivity, thermal conductivity and corrosion resistance.

1060 O aluminum alloy has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity. But they have lower strength than other alloys.

1060 O aluminum strip has high plasticity at annealed state and hardening phenomenon in semi cold hardening, good corrosion resistance, good weldability, poor machinability, but with extrusion and stretch forming high performance. The electrical conductivity of 1060 O strip is about 60%IACS. The density is 2.7 g/cm3.

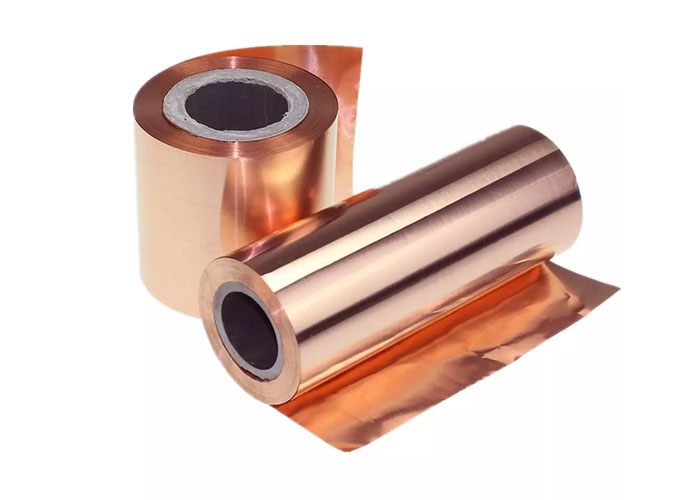

3.What is the 1070 O aluminum foil for transformer winding?

The 1070 O aluminum foil for transformer winding has the advantages of high conductivity, good corrosion resistance, high thermal conductivity and large extension ratio.

The annealing state is O.

The 1070 O aluminum foil for transformer winding can be used to make dry-type transformers, oil-immersed transformers and reactor windings.

The 1070 O aluminum foil for transformer winding has a density of 2.7 g/cm3 and the tensile strength is 60-105 MPa, which can meet the strength requirement of aluminum foil winding.

The elongation is 15-30%, which can meet the elongation requirement of aluminum foil winding. The electrical conductivity is ≥65%IACS or ≥60%IACS.

The 1070 O aluminum foil for transformer winding has good heat dissipation and does not increase the temperature rise of the coil during long-term operation, thus prolonging the service life of the coil. The use of 1070 O aluminum foil for transformer winding can reduce the mass manufacturing cost of transformers by 15%.

Advantages of 1070 O aluminum foil for transformer winding:

1. Good plasticity after annealing;

2. Easy to process and weld;

3. Excellent corrosion resistance;

4. High conductivity and thermal conductivity;

5. Low strength;

6. Good elongation (≥20%) and other characteristics.

4.What is the 1350 O aluminum foil for transformer winding?

1350 O aluminum foil for transformer winding is widely used in the transformer industry, such as oil-immersed transformers and dry-type transformers.

The 1350 O aluminum foil for transformer winding can be divided into two types: bare and coated.

The bare type is mainly used as the winding material of oil-immersed transformers, and the coated type is mainly used as the interlayer insulation material.

Features of 1350 O aluminum foil for transformer winding:

1. Aluminium foil 1350 has excellent elongation and tensile strength, suitable for winding forming;

2. Good plasticity, uniform thickness, no burr after stamping;

3. Excellent electrical conductivity and thermal conductivity properties;

4. Good corrosion resistance and weldability;

5. Smooth surface quality, low pinhole degree;

6. High temperature resistance, can withstand the test of high temperature 130℃.

What are the advantages of using aluminum strips for transformers?

Aluminum strip used in transformer winding has following advantages:

- It has excellent flexibility and can be made into thin sheets with a thickness of 0.08 mm or less.

- The surface oxide film is easy to remove and does not affect the insulation strength during winding.

- The elongation rate is high, and it can be stretched over 2 mm without breaking.

- Excellent plasticity, can be made into a variety of shapes.

- Good adhesion between layers is conducive to the formation of good coils by means of adhesive tapes or interleaving paper.

How to buy aluminum strips for transformers?

Buyers should find and purchase their transformer aluminum strips needs through sourcing from manufacturers and distributors.

To buy aluminum strips, the buyer should consider:

- The supplier’s experience in the industry.

- The quality of goods manufactured by the supplier.

- The financial stability of the supplier.

- The supplier’s delivery system.

To get a quote for aluminum strips you need to know below information:

- Quantity (Kgs/Tons)

- Size (Thickness x Width x Coil)

- Material Grade (1050,1060,1070, etc)

- Edge (Deburred/Round)

- Coil ID (200mm/300mm/400mm/500mm)

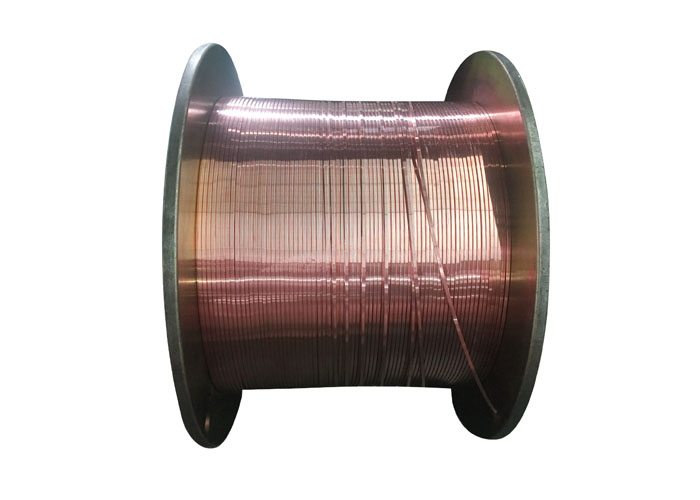

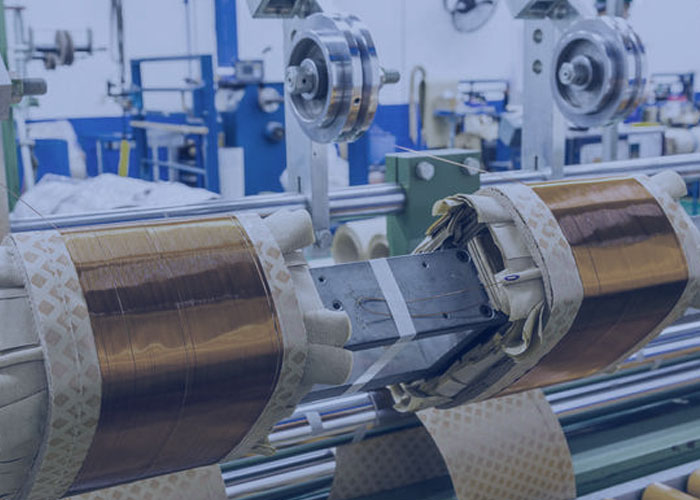

How about transformer aluminum strips production process?

The following will introduce you to the production process of transformer aluminum strips:

- The raw material enters the furnace and heats up to remove impurities;

- The ingot is cut into thick plates;

- Put the thick plate into a cold rolling mill for rough rolling;

- Put it into a hot rolling mill for finishing;

- Annealing by heating and holding at a certain temperature;

- Cutting outside by shearing machine;

- Packaging and transportation

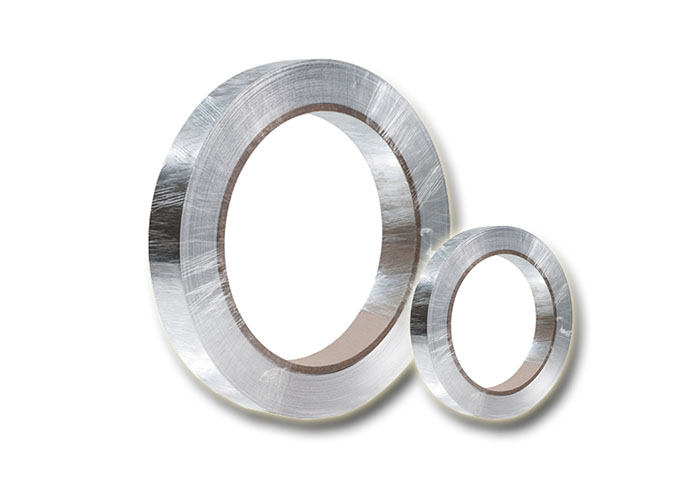

What are transformer aluminum strips packaging?

The packaging for transformer winding aluminum strip is mainly about wooden pallet and wooden box.